Materials Used in Splint Making: A Comprehensive Guide

Introduction

When it comes to immobilizing and supporting injured limbs, splints play a crucial role in facilitating the healing process. Over the years, advancements in technology and medical research have led to the development of various materials used in splint making. This blog aims to explore different types of materials, including plaster casts, fiberglass casts, thermoplastic splints, and metal splints, highlighting their characteristics, advantages, and applications. By understanding these materials, both patients and healthcare professionals can make informed decisions regarding the most suitable option for optimal recovery.

Plaster Casts

Plaster casts have a long and storied history in the field of medical practice, spanning centuries as one of the most commonly employed materials for splint making. Comprised of a mixture of plaster of Paris and water, these casts possess exceptional rigidity and provide crucial support to patients with injuries or fractures. The process of creating a plaster cast involves carefully layering dampened muslin bandages around the afflicted limb, allowing the plaster to gradually harden and solidify into a robust structure capable of immobilizing the injury.

One primary advantage that propels the continued use of plaster casts is their affordability, rendering them an accessible choice in various healthcare settings. Moreover, their malleability grants healthcare professionals the flexibility to mold the casts precisely according to the unique requirements of each patient. Furthermore, plaster casts offer remarkable breathability, facilitating adequate air circulation around the affected area and mitigating the likelihood of skin irritation.

Nonetheless, plaster casts do possess some inherent limitations. Their weight can prove cumbersome and uncomfortable for the wearer, potentially impacting their mobility and overall comfort. Additionally, plaster casts are relatively less durable compared to alternative materials, making them susceptible to cracking or chipping under certain circumstances. Moisture exposure poses another challenge for plaster casts, as they can deteriorate or lose their structural integrity when dampness seeps through the material.

Despite these drawbacks, advancements in medical technology have ushered in a range of alternative materials for splint making, such as fiberglass here we explain more about it.

Fiberglass Casts

Fiberglass casts have revolutionized the field of orthopedics with their numerous benefits. These casts have gained popularity in recent years due to their lightweight and durable nature, making them a preferred choice for treating fractures and other orthopedic injuries.

The construction of fiberglass casts involves combining layers of fiberglass fabric with a water-activated resin. Once the cast is applied to the injured limb, it is soaked in water, causing the resin to harden. This process forms a strong and rigid structure that effectively immobilizes the injured area, promoting proper healing.

One significant advantage of fiberglass casts is their waterproof nature. Unlike traditional plaster casts, fiberglass casts do not absorb water, allowing patients to engage in activities like bathing or swimming without compromising the cast’s integrity. This feature greatly enhances patient comfort and convenience during the recovery period.

Furthermore, fiberglass casts are radiolucent, meaning they do not interfere with X-ray imaging. This characteristic ensures accurate diagnosis and monitoring of the healing process. Doctors can easily assess the condition of the injury without the need for cast removal, reducing the risk of additional trauma or discomfort for the patient.

Another notable benefit of fiberglass cast is the wide range of colors they are available in. Patients can choose from an array of vibrant colors, allowing them to personalize the appearance of their cast. This feature can help boost morale and make the recovery process more enjoyable, especially for children who may find wearing a cast daunting.

In conclusion, fiberglass casts offer numerous advantages over traditional plaster casts. Their lightweight and durable nature, waterproof properties, radiolucency, and customizable appearance make them a highly desirable option for patients in need of orthopedic casting.

Thermoplastic Splints

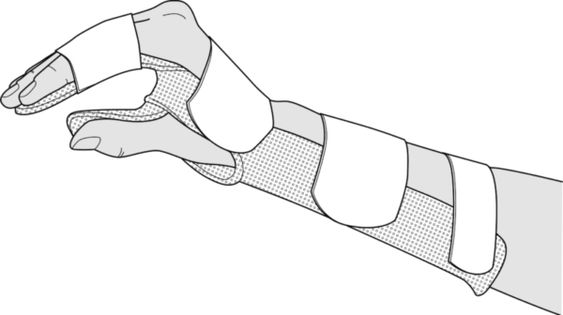

Despite the potential limitations, thermoplastic splints have gained popularity in various medical fields due to their numerous advantages. In orthopedics, they are frequently used for immobilizing fractures, sprains, and strains, providing stability and support to promote healing. The ability to mold them directly onto the patient’s limb ensures a precise fit, optimizing immobilization and minimizing discomfort.

In addition to orthopedics, thermoplastic splints have found applications in rehabilitation therapy. They can be utilized to maintain proper joint alignment, facilitate tissue healing, and prevent contractures in patients recovering from neurological conditions or surgeries. Their customizability allows therapists to adjust the splint’s shape and position to accommodate changes in the patient’s condition or therapeutic goals.

Moreover, thermoplastic splints have been embraced by pediatric healthcare providers. Children often require specialized splinting techniques to address their unique anatomical and developmental needs. The lightweight nature of thermoplastic splints makes them particularly suitable for young patients, who may find traditional rigid splints cumbersome and uncomfortable.

Another advantage of thermoplastic splints is their versatility in accommodating different levels of immobilization. By adjusting the thickness and rigidity of the material, healthcare professionals can tailor the splint to provide the appropriate amount of support for each specific case. This flexibility allows for targeted treatment while ensuring optimal patient comfort.

In conclusion, thermoplastic splints offer a versatile and customizable solution for immobilizing injuries across various medical disciplines. Their lightweight, conformable nature, along with their adjustability and ease of cleaning, make them an attractive option for healthcare professionals and patients alike. While they may have some limitations regarding durability and heat exposure, the benefits of thermoplastic splints make them a valuable tool in promoting healing and facilitating rehabilitation.

Metal Splints

Despite their weight, metal splints are favored in situations where stability is crucial, such as in cases of fractures involving multiple bones or traumatic injuries. The rigidity and robustness of metal splints ensure proper alignment of the affected bones, minimizing the risk of further damage and promoting optimal healing conditions.

Metal splints are also beneficial in situations that require prolonged immobilization. Due to their durability, they can withstand daily wear and tear, making them suitable for long-term use. This is particularly advantageous for patients with complex fractures or those recovering from extensive surgical procedures.

Moreover, metal splints can be customized and adjusted to accommodate individual patient needs. Orthopedic specialists can mold and shape the splint to conform precisely to the patient’s anatomy, ensuring a snug fit and optimal support. This personalized approach enhances patient comfort and prevents slippage or movement of the splint during daily activities.

In terms of maintenance, metal splints are relatively easy to clean and sanitize. They can be wiped down with disinfectant solutions, reducing the risk of infection and promoting a hygienic healing environment.

It’s worth noting that while metal splints provide excellent stability and durability, they may not be suitable for all individuals. Patients with metal allergies or sensitivities may experience adverse reactions or skin irritations when in contact with these materials. In such cases, alternative splinting options should be considered.

In summary, metal splints offer unparalleled strength, durability, and stability for severe fractures and complex injuries. While they may be heavier and less comfortable than other materials, the benefits of using metal splints in specific cases outweigh these drawbacks, providing patients with the necessary support and facilitating optimal healing conditions.

Conclusion

Choosing the appropriate material for splint-making is crucial in ensuring optimal recovery for individuals with limb injuries. Plaster casts, fiberglass casts, thermoplastic splints, and metal splints each possess unique characteristics, advantages, and applications. While plaster casts and fiberglass casts are widely used due to their affordability and lightweight nature, thermoplastic splints offer versatility and customization. In contrast, metal splints provide maximum stability and durability for more severe injuries. By considering these materials’ pros and cons, healthcare professionals can tailor their treatment plans to individual patient needs, promoting quicker healing and better outcomes.